In the medical device industry, toll manufacturing is an arrangement between a medical device manufacturer (MDM) and another entity that provides specialized manufacturing capabilities, skills, and technical knowledge of the materials and components required to produce the device.

Toll Manufacturing of Medical Plastics

If the device or component will be made from medical plastics, an experienced toll manufacturer, also called a toll processor or converter, will provide specialized expertise related to processing the materials. A capable toll converter will offer capabilities that include:

- Insight into medical polymer characteristics related both to their behavior in processing and to the performance requirements of applications.

- Expertise in the different medical polymer conversion processes that can be used to produce components for devices.

-

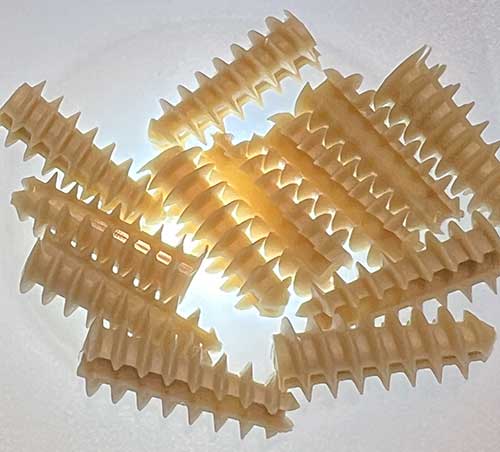

Injection molding yields high volumes of precision parts like these implantable PEEK suture anchors. Specialized polymer conversion equipment and process-related systems that ensure the manufactured components retain the desired properties of the plastic material.

- Logistical support and processes for packaging and delivery when required by the MDM.

- Flexible capacity and technical resources that can quickly adapt to unforeseen challenges.

In a toll manufacturing partnership involving medical plastic conversion into components or finished devices, MDMs typically provide the raw materials and the quality management protocol necessary for manufacturing what they require. The MDM may also request specialized packaging depending on the project. The toll manufacturer provides the production capabilities and resources necessary to produce the components for a device, or the device itself, from the polymer the MDM supplies.

In short, toll manufacturing or toll conversion of medical plastic products provides MDMs the specialized manufacturing equipment and skills that are best suited to efficient and reliable device production without using their own capital investments or staffing.

What the Toll Manufacturer Specializing in Medical Polymers Provides

In a toll manufacturing relationship, the medical plastics convertor works with the MDM to establish the optimum production method for the device, its design and material specifications, and the required quality system. The MDM specifies and purchases the material, often a proprietary formulation or highly specialized grade such as a long-term implantable plastic and supplies it to the toll processor. The toll processor then will work with the MDM to clarify the need for related services such as finishing, product identification and packaging.

Specific capabilities and value-added services the toll manufacturer provide include:

Expert Knowledge of Polymer Melt Behavior

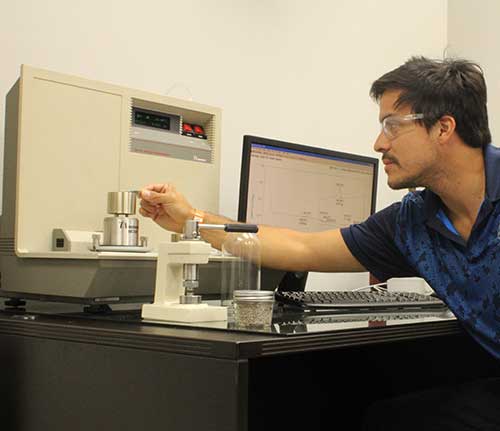

Polymer converters who offer toll manufacturing services specifically for medical polymers will have significant knowledge of how plastics behave in the melt stage during processing. They can analyze a plastic’s melt flow characteristics and use the data to determine how to align processing conditions and equipment to achieve the targeted performance from the polymer.

Many medical applications rely on devices developed from high-performance polymers like PEEK, PPSU or polysulfone. These specialty medical plastics are often difficult to process, especially in complex configurations with very thin or thick wall sections, or long lengths. Processing know-how is essential for conversion of these materials so that their property values are consistently maintained throughout the finished component.

A high level of expertise in melt flow analysis and process optimization is especially important with grades of these polymers that are formulated with specialized and often proprietary additives intended to enhance the performance of devices and components.

ISO Certifications and FDA Registration as a Manufacturing Facility for Final Devices

Toll converters with the relevant regulatory and quality credentials for manufacturing medical devices can facilitate the approval process for the MDM. Key qualifications a capable toll manufacturer can provide are FDA registration as a final device manufacturing facility, coupled with up-to-date certification for compliance with ISO 13485 and ISO 9001 standards.

Injection Molding Capacity

Most medical devices, because of the higher quantity requirements, are injection molded. The process is efficient and can yield finished parts with very minimal material waste. A key consideration is the actual capacity available for production. Production planning is essential. Toll converters should have ample capacity to handle spikes in demand and unanticipated growth to avoid extended lead-times for devices and risk loss of sales while waiting for new equipment to be installed. State-of-the-art machinery is often built to specification and can take significant time to procure, install, and fine-tune componentry.

Tool Building and Maintenance

Producing consistently high-quality medical plastic devices requires high quality tooling that is expertly and rigorously maintained. Toll processors with these capabilities work with their MDM client to finalize the design of the injection molding tooling, develop the required tool for the project, and validate its efficacy prior to production. Tool maintenance after each run and over the life of the device or component is also an essential capability in toll manufacturing that contributes to consistent quality and reliable lead times.

Dedicated Precision Machining Centers

While high unit volumes usually dictate injection molding capacity, machining can be beneficial as part of the toll convertor’s capabilities for early-stage prototyping to validate the combination of material and design. Under these circumstances, a toll injection molder with CNC machining centers dedicated to medical products provides an efficient option especially where schedules for agency submittals and device commercialization are tight.

An on-site CNC machining capability can also be beneficial for post-machining to add features to devices that are too complex to achieve by injection molding alone.

Machinable Shapes Extrusion

A toll manufacturer with the ability to extrude machinable rod and plate in the specified medical polymer can also be beneficial – especially when the specified polymer grade is proprietary or specialized and not readily available from typical volume-oriented custom extruders. These stock shapes can be extruded efficiently in quantities required for prototyping, and in higher volumes if the MDM elects to initiate agency testing and commercialization with the device or its components in machined form. Extrusion tooling for different sizes is relatively inexpensive, so different rod diameters and plate thicknesses can also be produced quickly to accommodate design changes for the machined parts.

Process Engineering Expertise

State-of-the-art equipment requires experienced polymer process engineers to realize the full capabilities of the machines. They ensure all equipment is outfitted with the right control systems, and calibrated, monitored and maintained to optimum conditions for each medical plastic and grade. Complexities include proper pre-drying of the polymer pellets, fine-tuning melt temperatures and pressures in the barrel and tool, and techniques to yield uniform parts regardless of wall thickness or dimensions.

Less technical but also critical aspects of high-quality processing include purging barrels and cleaning and polishing screws to avoid cross-contamination of resin into ensuing production runs. As their primary business, medical plastics processors are fully focused on investing in the state-of-the-art equipment and the required technical talent and quality systems to support the needs of their MDM customers.

Allocating Resources for Mutual Benefit

For many MDMs, allocating the necessary production space, investing in the physical equipment, and developing the skilled technical staff required for plastics processing dilutes their business focus. Conversely, medical plastics processors who provide toll manufacturing services make the investment in the facility, equipment and talent required to build on their core capability and strength. A close, collaborative relationship between the two entities gives MDMs high quality components for commercial success, while enabling the toll processor to continue to ramp up their ability to deliver those products consistently.

Toll Manufacturing vs. Contract Manufacturing

MDMs have options when establishing a manufacturing partnership. In addition to toll manufacturing or conversion, for example, MDMs may contract a partner to handle all elements of production for a device under a contract manufacturing agreement.

Basic Differences

A contract manufacturer essentially manages the entire production process for the MDM. In toll manufacturing, the processor provides a more specialized, focused service, such as injection molding the device. The toll manufacturer may also provide related conversion services, such as machining prototypes or production parts, or extruding machinable stock shapes in the specified polymer. Typically, the toll manufacturer or processor is part of the contract manufacturer’s supply chain.

Contract Manufacturing Services

The array of services that contract manufacturers provide their MDMs are broader. They routinely include:

- Sourcing raw materials required for production of the device and its components. In some cases, the contract manufacturer is also responsible for material selection and specification.

- Sourcing ancillary items such as packaging and labeling products.

- Inventory management including the finished devices, and materials required to make and package the device.

- Manufacturing and assembly either in-house or through a toll manufacturer. In the case of devices made from medical plastics, the contract manufacturer is supplying the polymer to the toll converter for producing the device or components.

- Packaging and shipping may be included in the contracted services. The contract manufacturer ships based on input from the MDM, and acts as part of the MDM’s logistics system.

Summary: Benefits of Toll Manufacturing and Contract Manufacturing

Contract manufacturers provide the capable resources for producing, assembling, finishing, packaging and shipping medical devices according to the MDM’s standards. They function seamlessly in the contract relationship and often appear to third party customers to be part of the MDM’s business system.

Toll manufacturing or toll processing of plastic medical devices allow MDMs to outsource technically complex elements of a project to experts in analytical testing, prototyping and various polymer conversion processes. The MDM avoids having to allocate capital investments and staffing to a non-core business activity and can focus resources on product development, regulatory approval and device commercialization.