Polyetheretherketone, or PEEK, is a semi-crystalline thermoplastic polymer. It is one of the most stable polymers in existence and retains its stability even when subjected to extreme temperatures and forces. PEEK is considered a high-performance polymer, which means it can be used in the kind of applications that would quickly wear out and/or destroy other materials. Because it is so durable and resilient, PEEK is found in rocket engines, race cars and in down well oil & gas equipment.

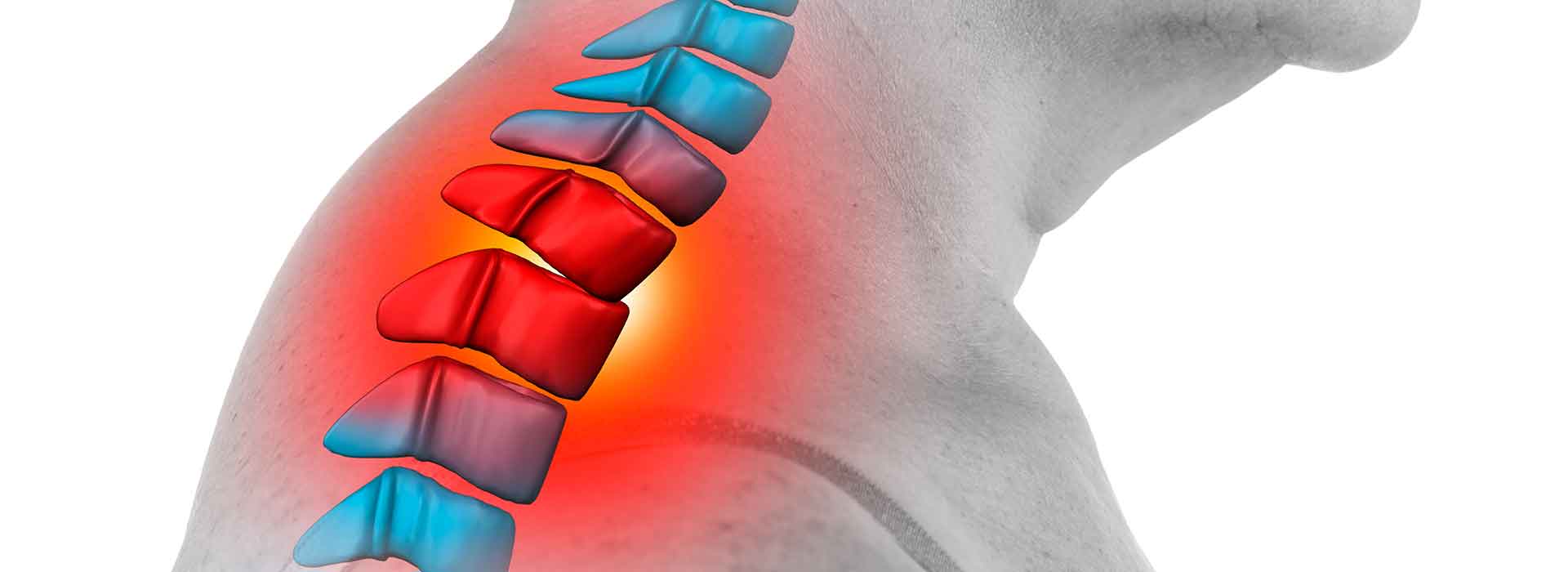

PEEK has also emerged as an advanced biomaterial and is already a frontline choice for spinal implants and joint replacement applications. It is also a useful material in trauma fixation, orthopedic and cardiovascular devices. Additionally, PEEK components are also valuable for analytical and laboratory equipment, as well as surgical instruments.

What kind of material is PEEK, then? It’s a versatile, durable and safe material that has near-limitless potential in a variety of medical applications.

What are PEEK’s standout properties?

As a high-performance polymer, PEEK possesses an impressive range of material properties. Some of those properties include:

1. Bone-like modulus – PEEK possesses a modulus that is extremely similar to cortical bone. It is stiff enough to behave like bone but isn’t so stiff that it bears a disproportionate amount of weight. This protects neighboring bone from mineral density loss and ensures the material behaves in a predictable manner once placed.

2. Radiolucent – PEEK was introduced to medicine because of its bone-like composition and because it does not interfere with medical imaging. In its unfilled state, PEEK does not generate visual artifacts on X-rays, CT and MRI scans. If additional opacity is required, Barium Sulfate can be mixed into the polymer. PEEK’s radiolucent properties can be customized to the patient and the application.

3. Resistance to high temperatures – PEEK may be a thermoplastic, but it’s one of the more difficult polymers to affect with heat. PEEK components can still function like normal when the temperature climbs to 480 degrees Fahrenheit. PEEK doesn’t melt until the thermometer hits about 660 degrees Fahrenheit, so heat is not a concern for PEEK in medical applications.

4. Hydrolysis and organic environment resistance – PEEK does not deteriorate in the presence of water or organic materials, which is another reason why the polymer is particularly well-suited for implantation. With strong hydrolysis resistance, PEEK implants are perfect for dentistry, and perfect for instruments that must be sterilized regularly. With resistance to organic attack, PEEK implants can be used safely throughout the human body.

4. Hydrolysis and organic environment resistance – PEEK does not deteriorate in the presence of water or organic materials, which is another reason why the polymer is particularly well-suited for implantation. With strong hydrolysis resistance, PEEK implants are perfect for dentistry, and perfect for instruments that must be sterilized regularly. With resistance to organic attack, PEEK implants can be used safely throughout the human body.

5. Unmatched wear and abrasion resistance – PEEK has a low coefficient of friction and resists abrasive damage to an impressive degree. PEEK’s resiliency is one of the polymer’s standout traits, as it will retain its shape and function even when subjected to constant wear. PEEK’s abrasion resistance is valuable for dental implants, where there’s a lot of chewing, grinding and clenching. PEEK’s wear resistance ensures it is unaffected by these natural, everyday forces.

6. Lightweight and comfortable – PEEK is much lighter than metal, and this makes a difference when the polymer is used in prosthetic or dental components. Steel has six times the specific gravity of PEEK and aluminum has twice the specific gravity of PEEK. As aluminum is prized for its lightweight nature, it’s clear that PEEK holds even more of an advantage in this area.

PEEK can be augmented with various additives, including Carbon Fibers that reinforce the polymer’s strength, stiffness and structure. Even with additives, PEEK maintains an impressive strength-to-weight ratio.

7. Versatile – PEEK can be extruded, injection molded and machined, while also produced to extremely tight tolerances. PEEK is a natural material to use with CAD and CAM technology, as it can be shaped extensively. With CAD and CAM, PEEK components can be designed using 3D imaging and produced in intricate shapes and designs.

PEEK’s versatility in this regard is valuable for medical device manufacturers. If a medical facility only requires a small batch of components, machining the components often makes economic sense. If a medical facility needs thousands of components, injection molding can produce PEEK components at a rapid clip and typically at a lower cost than machining.

As a high-performance thermoplastic polymer, PEEK possesses an array of properties that make it stand out, even among other high-performance polymers.