High performance polymers like PEEK have been used in implantable devices for decades, and its potential in orthopedic implants is nearly limitless. PEEK is safe, bioinert, flexible and strong, so it is a viable and often superior alternative to ceramic, metal and resorbable materials.

PEEK also has advantages on the processing side, as it can be shaped and produced in an array of sizes and shapes, including extremely intricate and delicate shapes. With its processability, PEEK has been adapted for most major orthopedic applications, including total joint replacement procedures.

Why PEEK is a Great Fit for Orthopedic Implants

PEEK’s material properties make it an ideal choice for many medical applications, including orthopedic procedures. Some of those standout material properties include:

• Bone-like modulus – As a high-performance polymer, PEEK is more flexible than metal and ceramic, and this flexibility is an important property to have in an orthopedic device. In fact, PEEK’s flexibility is similar to that of cortical bone, so it moves, flexes and bears weight much like bone. As orthopedic implants are designed to replace the motion and strength of bone, a bone-like modulus is highly valuable.

• Reduces stress shielding – Implants that bear too much weight reduce the load on neighboring bone, and while this sounds like a positive, it can cause long term complications. Stress shielding occurs when the implant is bearing so much weight that the body compensates by reducing bone mineral density in nearby bone. Because bone adapts favorably when bearing a load, orthopedic implants must preserve this important trait.

• Modifiability – PEEK is found in so many applications because it is endlessly modifiable. Specifically, PEEK can be mixed with various additives to alter its material properties, including its flexibility and radiopacity. The addition of chopped carbon, for example, will impart stiffness, fatigue resistance, and improve the material’s ability to bear weight. In some orthopedic applications, this is essential to have.

PEEK’s radiolucent properties can be modified with the use of additives. In its natural state, PEEK is transparent on X-ray, MRI and CT imaging. With the addition of additives, like Barium Sulfate, the polymer becomes opaque for viewing on imaging scans.

• Processability – No two patient anatomies are the same, but orthopedic implants must still be kinesthetically compatible with every patient. That’s a manufacturing challenge, as every component must be produced to extremely tight tolerances.

Of all the biomaterials, PEEK is one of the most versatile when it comes to processing. It can be injection molded, machined, extruded and produced into extremely thin films. Fine adjustments can be made to each process to ensure the component meets tolerance benchmarks every time. PEEK’s versatility in this regard means it can be fitted to every patient’s anatomy with little difficulty.

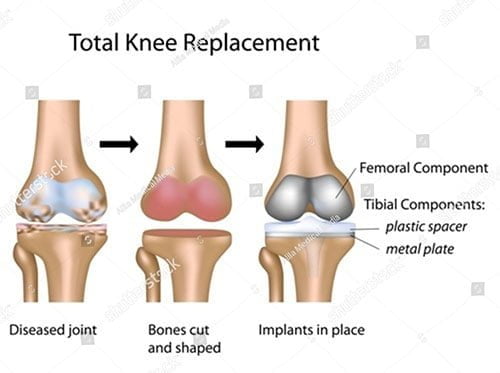

PEEK in Knee Arthroplasty

PEEK’s effectiveness as a weight-bearing component in other applications has made it an intriguing choice for arthroscopic procedures. Multiple studies have been conducted on how well PEEK performs as a femoral component and a safe alternative to cobalt chromium.

Carbon Fiber reinforced (CFR) PEEK is of particular interest in knee arthroplasty applications and is produced by adding chopped carbon to the polymer. It provides additional stiffness and weight-bearing capabilities over natural PEEK, while also possessing favorable wear properties.

PEEK in Hip Arthroplasty

Hip arthroplasty is becoming more common as the world’s population grows older, and improved orthopedic implants are critical in this area. During hip arthroplasty, both the femoral head and the acetabular cup can be replaced with artificial components.

CFR PEEK can be incorporated into acetabular components, as this is where weight-bearing is needed the most. A few studies have looked at CFR PEEK’s ability to withstand wear as an acetabular material. One of those studies, published in the Journal of Engineering in Medicine, found that after articulating CFR PEEK femoral head for one million cycles, the wear rate was only about 1mm3, which is well within acceptable limits.

PEEK in Shoulder Arthroscopy

PEEK is able to solve a lingering problem in shoulder arthroscopic procedures – namely, the fear that suture anchors may degrade too quickly, which necessitates additional surgeries. PEEK is a frontline choice for suture anchors given its superior load-to-failure strength radiolucent qualities.

PEEK in Knee Arthroscopy

Knee arthroscopy is also becoming more common, as it can be performed as an outpatient procedure. It’s also more sophisticated than in years past and can be used to treat conditions like meniscus tears. Anchoring components are important in knee arthroscopy, and because PEEK features excellent pullout strength and radiolucency, it’s ideal in this area.

PEEK’s material properties make it a natural choice for orthopedic procedures. It’s biocompatibility and safety have been demonstrated over decades of use. It is more resilient and durable than other biomaterials.PEEK’s material properties make it a natural choice for orthopedic procedures. It’s biocompatibility and safety have been demonstrated over decades of use. It is more resilient and durable than other biomaterials.