PEEK is a respected dental material and is quickly replacing metal components in a variety of applications. PEEK is among the most stable high-performance polymers in existence, which is vital for any biomaterial. Biostability and compatibility are only the beginning for PEEK, and its potential as a dental material goes much further. The polymer has been in use in medical devices for a couple decades, and it demonstrates an impressive array of medicine-friendly properties.

PEEK’s Advantages as a Dental Material

PEEK’s Advantages as a Dental Material

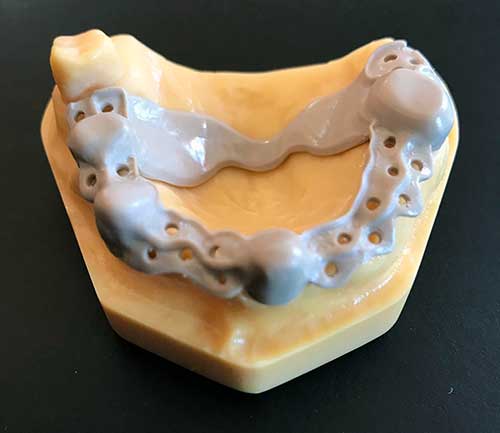

There are numerous reasons why PEEK is an ideal dental material. It is a frontline choice for dental abutments, removable partial dentures and fixed prosthetic frameworks, and researchers are optimistic about its potential in additional applications.

Why is PEEK an effective dental material?

1. Biocompatibility – PEEK’s biocompatibility has been proven and multiple studies have confirmed its nontoxicity. Even after use in thousands of patients, PEEK is the ideal choice compared to metal, which causes an allergic reaction in as much as 15 percent of the population.

PEEK components are found in spine implants, trauma fixation devices, hip and knee arthroplasty and other medical devices. In every instance, there have been no issues with PEEK’s safety in the body.

2. Mechanical properties – PEEK possesses a superior strength-to-weight ratio, and this is especially important for dental implants and devices. Compared to metal, PEEK is lighter and more comfortable for patients. This added comfort doesn’t compromise durability either, as PEEK can handle abrasive and compressive forces without losing its integrity. This polymer is immune to corrosion and absorbs water at a minimal rate, so it can last for years without suffering a drop in performance.

3. Ability to be machined – Dentists are relying on computer-assisted design (CAD) and machining (CAM) more than ever, and PEEK is a perfect fit for this. An essential feature in modern dental devices is a precise fit with the patient’s anatomy, and CAD/CAM are necessary to create it. This ensures the device will rest comfortably, functional optimally and last as long as possible.

If PEEK is machined to manufacturer specifications, it will retain its properties after milling. This added stability allows for more flexibility during the design stage and makes it easier for dentists to fit their patients with a custom device.

PEEK’s easy compatibility with CAD/CAM methods also means it can be processed quickly and consistently. In short, PEEK devices can be reliably and quickly produced.

4. Flexibility – This high-performance polymer is durable, but not stiff. When unfilled, it offers a modulus that is similar to cortical bone, making PEEK a strong, flexible dental material. With its extra flexibility, PEEK will feel natural in the mouth and remain resilient even after years of biting and chewing. Dental devices must maintain their shape while being subjected to constant stress, and PEEK is among the best polymers at doing so.

5. Radiolucency – PEEK’s bone-like modulus and radiolucency were the two traits that initially drew medical researchers to PEEK, and it remains one of the polymer’s standout properties. In recent years, research into PEEK dental implants has shown that the material has considerable potential in this area.

PEEK’s radiolucency is a valuable trait when the material is used in any implant procedure. Once implanted, the polymer will produce no visual interference on X-rays, CT or MRI scans. As X-rays are critical for dental diagnostics, PEEK’s non opacity on images will ensure dentists can do their job in monitoring their patient’s health. In instances where PEEK’s superior radiolucency could be considered a hindrance, the polymer can be augmented with additives such as Barium Sulfate to generate better contrast.

6. Aesthetics – Just as PEEK can be fabricated to a custom shape with ease, it can be precisely color matched to the patient. Metal, by contrast, is often impossible to hide in the mouth, and this is a noted issue for patients.

PEEK is an easy dental material to integrate into the oral cavity, as its color can be modified during processing. Even full dentures can be fabricated to appear natural, ensuring patients can speak, smile and eat with confidence.

7. Taste neutral – Yet another concern with metal devices is that they produce a metallic taste for a lot of patients. This isn’t a health concern, but is a constant frustration for patients who don’t want to be reminded that they have a denture or framework in place.

Fortunately, PEEK is a taste-neutral dental material, giving patients one more layer of comfort that they can’t get from metal devices.

Although this is already a compelling list, the most important thing to remember with PEEK is that it has incredible untapped potential as a dental material. It’s reasonable to expect frequent improvements in the material’s application. With its present capabilities and future development, PEEK is poised to be the first choice in dental device materials before long.