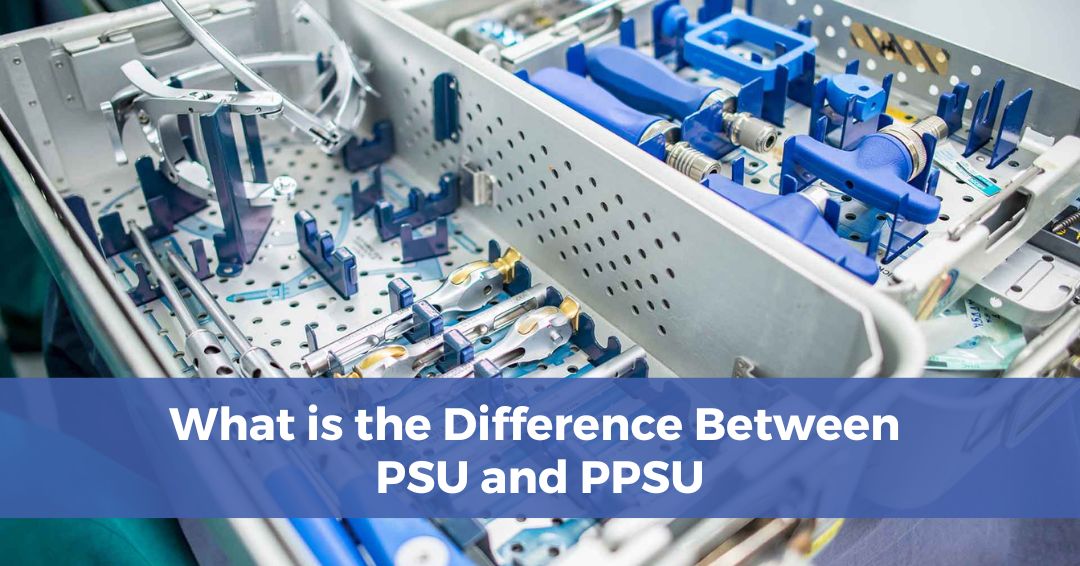

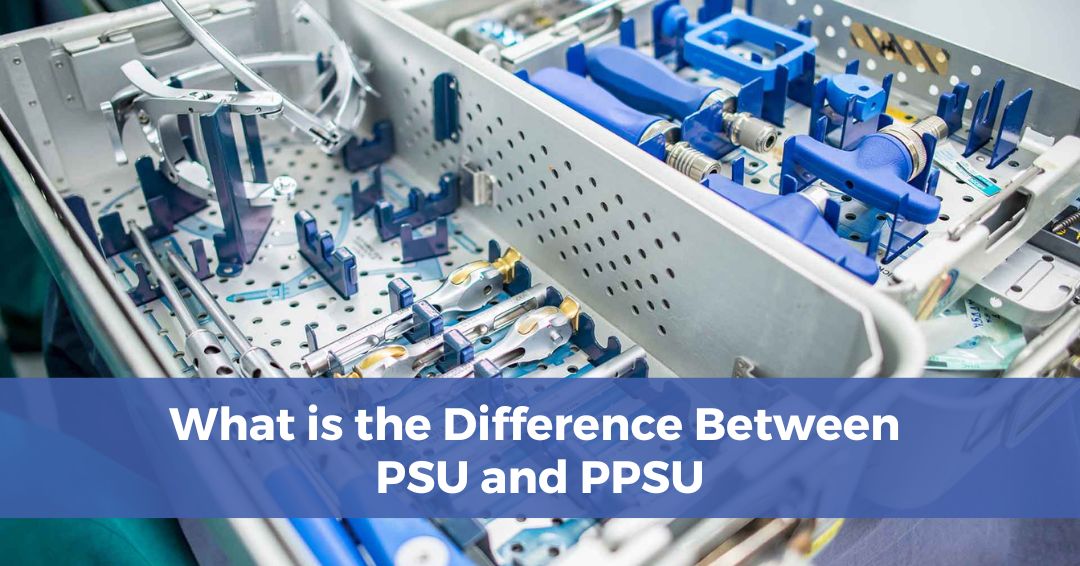

What is the Difference Between PSU and PPSU

Polysulfone (PSU) and polyphenylsulfone (PPSU) are both members of the sulfone family of amorphous polymers. They are considered high performance plastics and are widely specified

Polysulfone (PSU) and polyphenylsulfone (PPSU) are both members of the sulfone family of amorphous polymers. They are considered high performance plastics and are widely specified

Polysulfone is a member of the sulfone polymer group, a class of engineering thermoplastics with excellent mechanical and thermal properties and the ability to resist

Medical device manufacturers rely on prototyping to convert a concept into a material form that gives designers, engineers and the marketing team an important first

In hospitals, much is demanded of medical plastics. They must be safe, durable, comfortable to handle and cost effective. They must also be compatible with

Several polymers have been adopted for widespread use in medical devices, trays, instruments, and other applications used in hospitals, ambulatory surgery centers, as well as

Historically, health care facilities used metals or premium high-performance biocompatible plastics for surgical instruments that could be sterilized after each use. More and more, however,

The US Food & Drug Administration (FDA) is the primary regulatory body for medical plastics and the devices they are used to create. According to

Implantation testing is one of several biocompatibility tests, reserved for medical devices that are placed in the body’s internal tissue, bone or cavities. As such,

Medical plastics have been adapted for use in many healthcare fields, including spinal fusion, trauma fixation, orthopedics, cardiovascular, dentistry and prosthetics. Medical polymers are also

Medical plastics are of great value to the healthcare industry and are used in everything from surgical instrumentation to life-preserving cardiovascular devices. Medical plastics come