Genesis offers our specialized extrusion, calendering, injection molding and machining capabilities on a tolling basis to convert customers’ medical polymers into the stock shapes, films and components required for their medical devices.

What does it mean if a manufacturer offers tolling services?

Medical device production is frequently complex, involving many processes that may be prohibitively difficult or expensive for some original equipment manufacturers (OEMs) to manage. To overcome this, OEMs may turn to other manufacturers to provide needed expertise, equipment, labor, or a combination of the three. In this context, the OEM is the source company, and the third-party manufacturer is providing tolling services to its OEM client. Tolling services, or toll processing, can be a mutually beneficial professional relationship between an OEM and its manufacturer partner(s). Here’s how it typically works:The source company provides the necessary material –

In a toll processing arrangement, the source company (usually the OEM) is responsible for furnishing the raw material or partially finished components to the processor.

The processor provides the necessary skill –

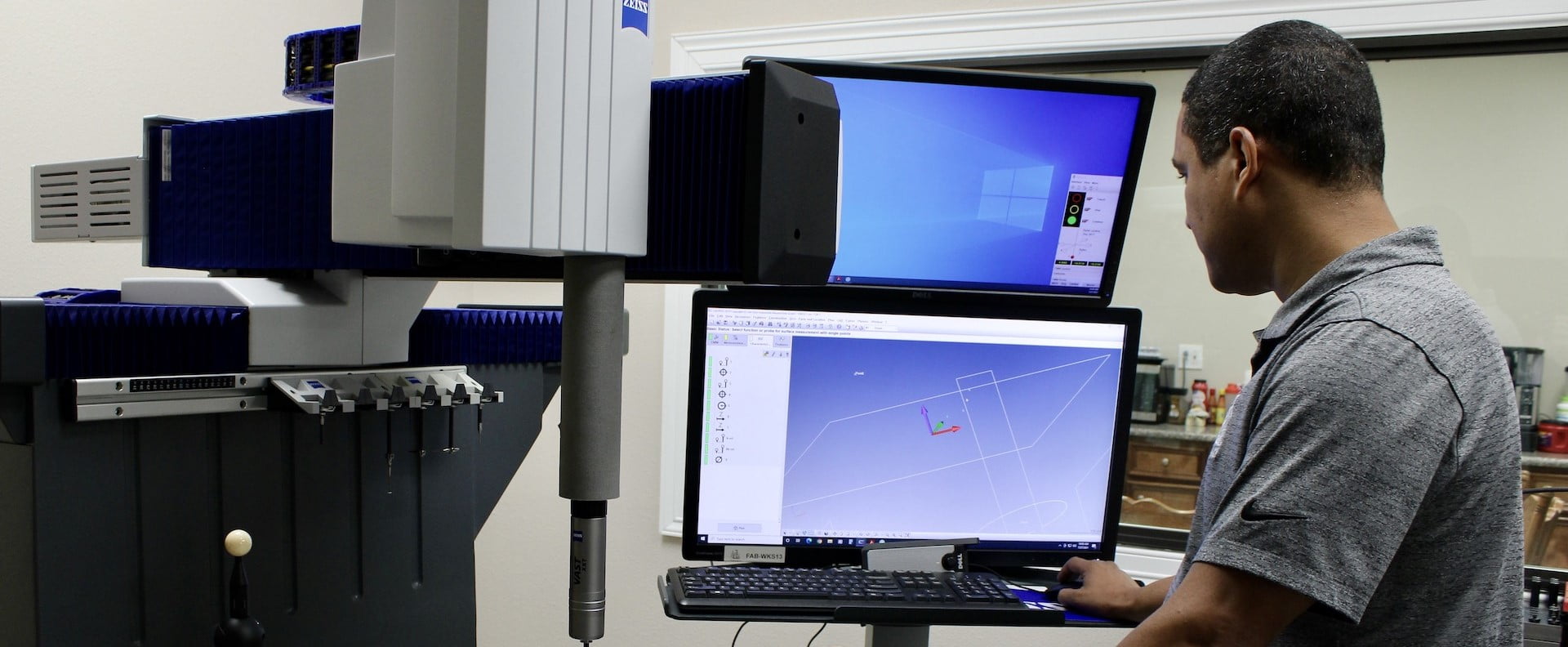

The third-party manufacturer (typically a processor) assists in device production by leveraging its know-how, specialized equipment, additional manpower, or anything that the source company requires to complete manufacturing.

The source company pays a “toll” for the processor’s expertise –

In return for the processor’s assistance in manufacturing, the source company pays a fee. The OEM receives their components and the processor profits, so both parties benefit.

There are several reasons why OEMs consider bringing in a third-party to complete manufacturing, and they are particularly relevant to smaller companies.How can tolling services benefit a smaller OEM?

Few industries are developing as rapidly as the medical device industry. With more and more encouraging treatment options emerging every day, there’s room for an increasing number of device manufacturers. Many of these manufacturers are ambitious but small, to the point where a lack of resources could hamper the company’s long-term goals. Opting for tolling services makes sense for these OEMs, and here’s why:1. It allows OEMs to focus on what they do best – Every OEM is different in terms of what they bring to the industry. Some may possess leading-edge device designs but may not have the equipment needed to bring those designs to reality. These OEMs could commit a lot of capital to equipment and manufacturing processes, but there’s always risk when tying up so much capital.

Tolling services offer a low-risk alternative to this problem, so OEMs can sort out their manufacturing processes and reserve resources for other, perhaps more critical departments, like R&D or marketing.

2. It helps fill in any manufacturing gaps – Tolling services are provided on-demand, and like with any on-demand service, they are available whenever they are needed. If an OEM’s processing needs change, they can leverage tolling services through another manufacturer to ensure component performance and reliability.

This is a common practice in medical device manufacturing because modern medical devices are often manufactured from relatively new biomaterials, including high performance polymers. It takes specialized equipment and processes to handle these biomaterials, and smaller OEMs may not have anyone on staff with such knowledge. Partnering with a polymer processor can inject this essential knowledge into manufacturing, so even if the source company is unfamiliar with some of the processes, component quality won’t suffer.

In some cases, tolling services are needed to scale up manufacturing quickly. The OEM may possess the knowledge and equipment they need to produce a quality component, but they may not be able to produce at volume. Bringing in another manufacturer can boost production, at least until the source company can scale up their own operations.

3. It saves time – Time is at least as important as money, and OEMs can save both when electing for tolling services. Timewise, tolling services allow OEMs to bring their product to market much faster than if they were to handle all manufacturing in-house. It can take months to locate, purchase and install the right equipment. It can take months to hire and train the right people. With tolling services, these time-consuming steps are unnecessary, which means smaller OEMs can compete right away.

What are the differences between tolling and contract services?

If an OEM does choose to involve a third-party manufacturer, they can opt for tolling services or contract the manufacturer instead. The two approaches are more similar than different, but the differences are key. For example:- Contracted manufacturers provide raw material – When an OEM opts for tolling services, they determine exactly what parts of the process the third-party will handle. In this arrangement, the source company is responsible for providing raw material or unfinished product.

When an OEM contracts a third-party manufacturer, they hand the entire production process over to their manufacturer partner. This includes furnishing all raw material, so it is the contracted company’s responsibility to set up an efficient supply chain. This allows the contracted manufacturer to provide cost efficient components to their client.

- The contracted business has a major influence on component quality – Under a tolling services arrangement, the third-party manufacturer may have only a modest impact on the component’s quality. It depends on what parts of the process they are responsible for.In a contracted services arrangement, the contracted manufacturer is involved in every step of production, so component quality is reflected in the manufacturer’s ability and attention to detail.

- Contracting a manufacturer simplifies cost analysis – Once a manufacturer is contracted, they handle everything related to component production. That means all production costs are managed by the contracted business, and they price their services to account for these costs. The OEM only has one number to consider—the final price that the contracted manufacturer charges per component. This one-number simplicity can help OEMs make faster, more cost-effective decisions.