PEEK enhances a variety of vascular medical devices

High performance polymers are a fertile area of medical research and engineering, and vascular medical devices made from PEEK represent a new, promising area of focus. Implanting devices around the heart has always presented challenges, but newer procedures preclude the need for risky surgical maneuvers. Vascular medical devices make many of these safer procedures possible, and, increasingly, PEEK is a material of choice for those devices. With its unmatched modulus, mechanical strength and radiopacity, PEEK is a natural fit for the vascular system.

Why is PEEK an ideal material for vascular medical devices?

Vascular medical devices are often steered through the complex network of blood vessels that make up our cardiovascular system. As blood vessels are intricately organized and vulnerable to trauma, biomaterials must possess particular traits to handle this environment.PEEK is emerging as a frontline choice for vascular medical devices as it offers those traits, which include:

- Pushability and navigation – Almost all vascular medical devices consist of some amount of tubing, and this tubing is what is snaked through the body’s blood vessels. Ideally, vascular tubing offers both pushability and navigation qualities, as this ensures controlled, easy movements through the vessels. Pushability refers to the amount of force required to push the tubing through the vessels, and the less force needed, the better. PEEK offers excellent pushability because it possesses an ideal flexural modulus and produces little friction. With its inherent flexibility and low friction, PEEK tubing retains its pushability even as more and more of the vessel’s internal walls are contacted. This reduces the likelihood of causing trauma and allows for precise device placement. Navigation refers to the tubing’s ability to compensate for the many twists and turns found inside the body’s vascular network. Device manufacturers often have to find a middle ground between pushability and navigation, because as one improves, the other tends to worsen. Fortunately, PEEK maintains strong navigation qualities even with its excellent pushability, again due to its flexural modulus. The result is medical tubing that can move through the vascular environment will little trouble.

- Buckling resistance – Vascular medical devices must resist buckling to ensure proper device function. PEEK, though flexible, is still rigid enough to resist kinking, and is superior to almost all other polymers in this regard.

- Radiopacity – Following device placement, the surgical team should be able to monitor the patient’s progress using regular medical imaging. It is critical, then, that any vascular medical devices remain visible on these images. PEEK’s radiopacity is one of the material’s standout traits, as it can be modified for the application. In applications where no radiopacity is desired, natural unfilled PEEK provides it. If a degree of radiopacity is needed, which is again the case for vascular medical devices, it can be increased with the use of additives like barium sulfate.

- Temperature and electrical resistance – PEEK’s capacity as an electrical isolator has been well-established, and it is used as such in multiple industries. In medicine, PEEK’s extremely high temperature and electrical resistance makes it a natural fit for many vascular medical devices. That’s because it can prevent accidental electrical discharge and shock, while retaining its physical properties.

- Biocompatibility – PEEK’s biocompatibility is another one of the material’s demonstrated, essential traits. Extensive research into PEEK’s cytotoxic, genotoxic and immunogenic potential has found no cause for concern, and patient reports back this up. PEEK has been in use for nearly 20 years in various medical application, including spinal fusion and trauma fixation, so it is safe and inert when placed in the body.

- Ease of sterilization – PEEK offers widespread resistance to chemicals, both inorganic and organic. It is also extremely resistant to hydrolysis and is practically unaffected by prolonged exposure to hot water. PEEK offers outstanding resistance to repeated conventional sterilization methods including autoclave (steam), gamma radiation, and Ethylene Oxide (EtO). As such, it is easy to sterilize prior to use in a patient.

PEEK clearly has strong potential in vascular medical devices for the above reasons, including use in new, less invasive surgeries.

How is PEEK being used in vascular medical devices?

PEEK’s use in vascular medical devices is rapidly expanding, as the material has shown itself to be an ideal choice for tubing and catheters. For this reason, it can be adapted for use in many medical technologies and procedures, including:

- Stent placement – Stents are placed in weakened or tight arteries to facilitate blood flow. The stent is delivered through the vascular system, and PEEK tubing can be relied on for this task.

- Transfemoral heart valve implantation – During transfemoral heart valve implantation, or TAVR, a new valve is implanted without removing the existing, damaged valve. It’s a valve-within-valve approach, and many TAVR surgeries involve a delivery system that includes PEEK components. Specifically, large diameter PEEK tubing is valuable for TAVR, for its pushability and navigation qualities.

- Ablation catheters – Ablation catheters are used to scar the heart using precise bursts of energy. The resulting scar tissue limits the spread and action of electrical impulses, which is needed when part of the heart has been damaged. Because PEEK has demonstrated strong electrical isolation capabilities, it is utilized in ablation catheters.

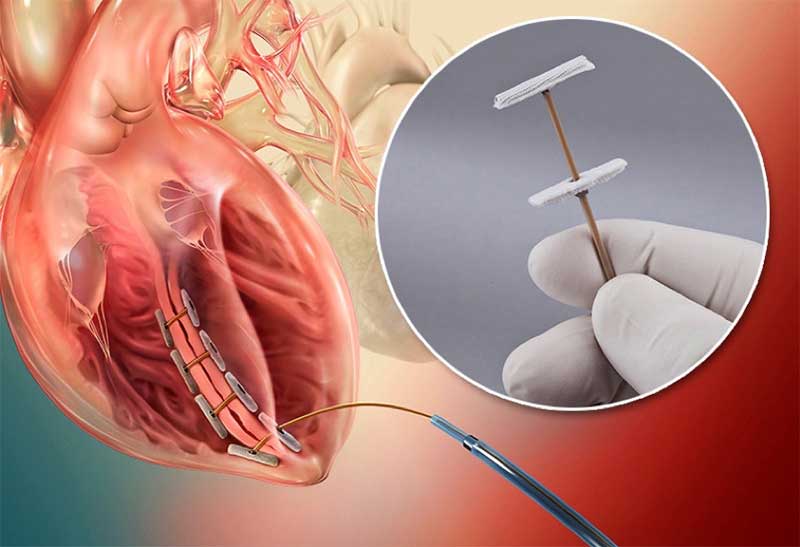

- Less invasive ventricular enhancement – Less invasive ventricular enhancement, or LIVE, is an emerging alternative to invasive forms of left ventricle repair. It is often needed following a heart attack or after a history of coronary heart disease, which can result in ischemic cardiomyopathy. During the LIVE procedure, an anchor is implanted over the left ventricle that serves to support its function. The anchor stabilizes the ventricle walls and the assembly is often made from PEEK components. PEEK works well for LIVE procedures because it is flexible and withstands the mechanical action of the heart well.

Vascular medical devices made from PEEK exhibit an impressive range of qualities, including excellent flexibility, resiliency and biocompatibility.