The melt flow characteristics of Radel 5000 PPSU enable processing by extrusion and by injection molding. This can facilitate transitioning from parts machined parts to injection molded components where the material specification must be maintained exactly.

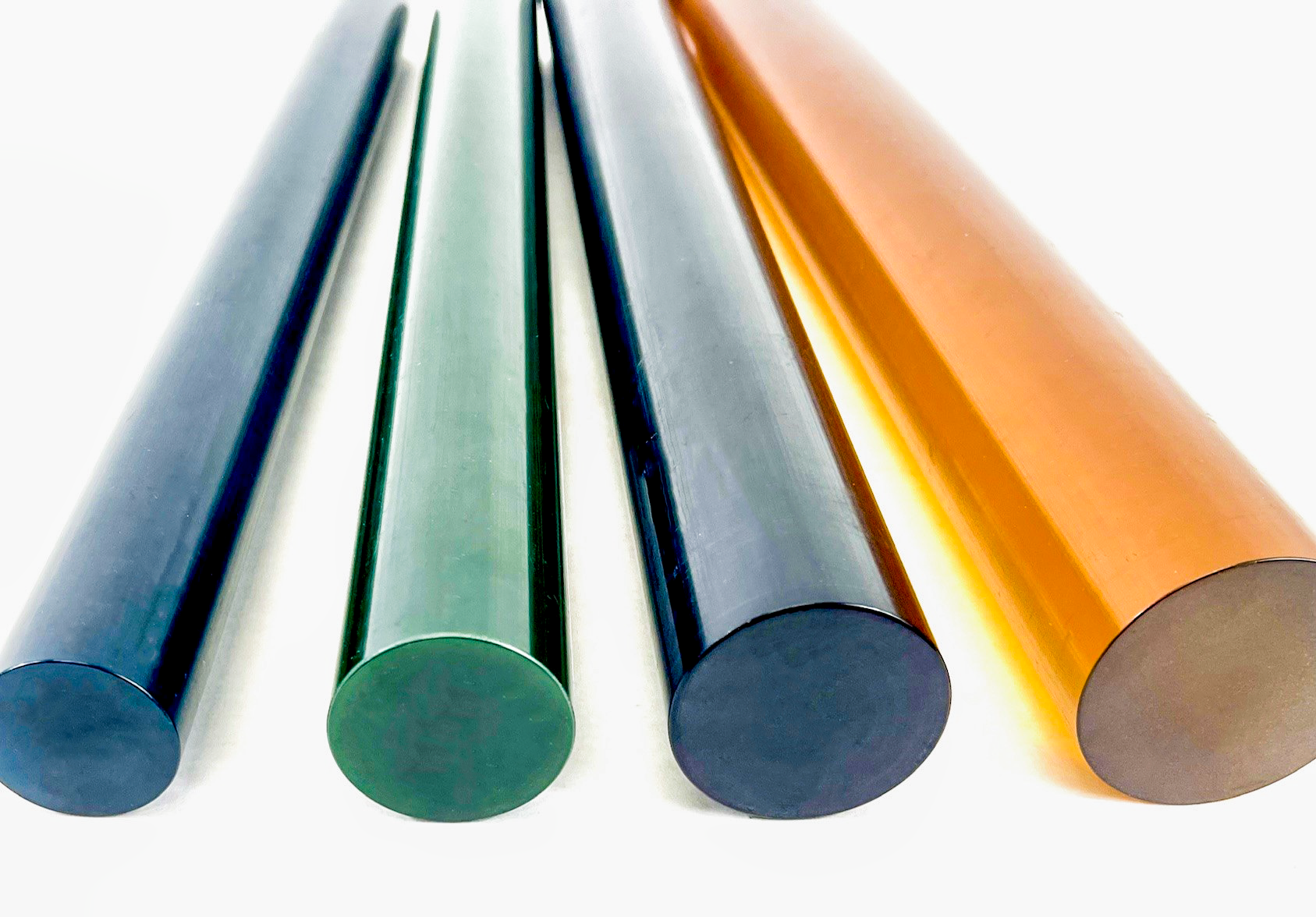

5000 resin has a transparent amber tint in its natural form. Its transparency makes it easily colorable, and a wide selection of typical healthcare opaque colors are available.

What are the Performance Features of Radel 5000 PPSU?

Radel 5000 has the hydrolytic stability, chemical resistance and ability to withstand repeated sterilization cycles common to all Radel PPSU grades. Compared to many other high-performance plastics, it retains its toughness over far more cycles in steam, ETO gas, vaporized hydrogen peroxide and gamma radiation. Radel 5000 also offers high stiffness and toughness.

What is Radel 5000’s Biocompatibility Compliance?

Based on its compliance with ISO 10993 biocompatibility testing, Radel 5000 can be used in applications that are in contact with bodily tissue and fluids for up to 24 hours. This has led to its use in injection molded fluid delivery devices as well as joint replacement trials machined from semi-finished shapes.

What are Typical Medical Device Applications for Radel 5000 PPSU?

The physical properties and resistance to degradation in sterilization of Radel 5000 PPSU are behind its use in machined and injection molded applications such as surgical tools and handles.

Its color range, resistance to cleaning agents and UL ratings are advantages for applications such as injection molded housings and components for electrical and electronic surgical and diagnostic equipment.

Genesis Medical Plastics Capabilities in Radel 5500 PPSU

Specifications –

SEMI-FINISHED SHAPES AVAILABILITY

Rod diameters

- 4mm – 152.4mm

- Custom & larger diameters on request

Plate thicknesses

- 4mm – 31.75mm

- Larger thicknesses on request

- Maximum width 610mm

All semi-finished shapes are made to order, with reasonable minimums.