Radel is a polyphenylsulfone (PPSU) polymer with properties that have made it a widely specified material for healthcare equipment and medical devices. It can be used for medical devices that are implanted for up to 24 hours.

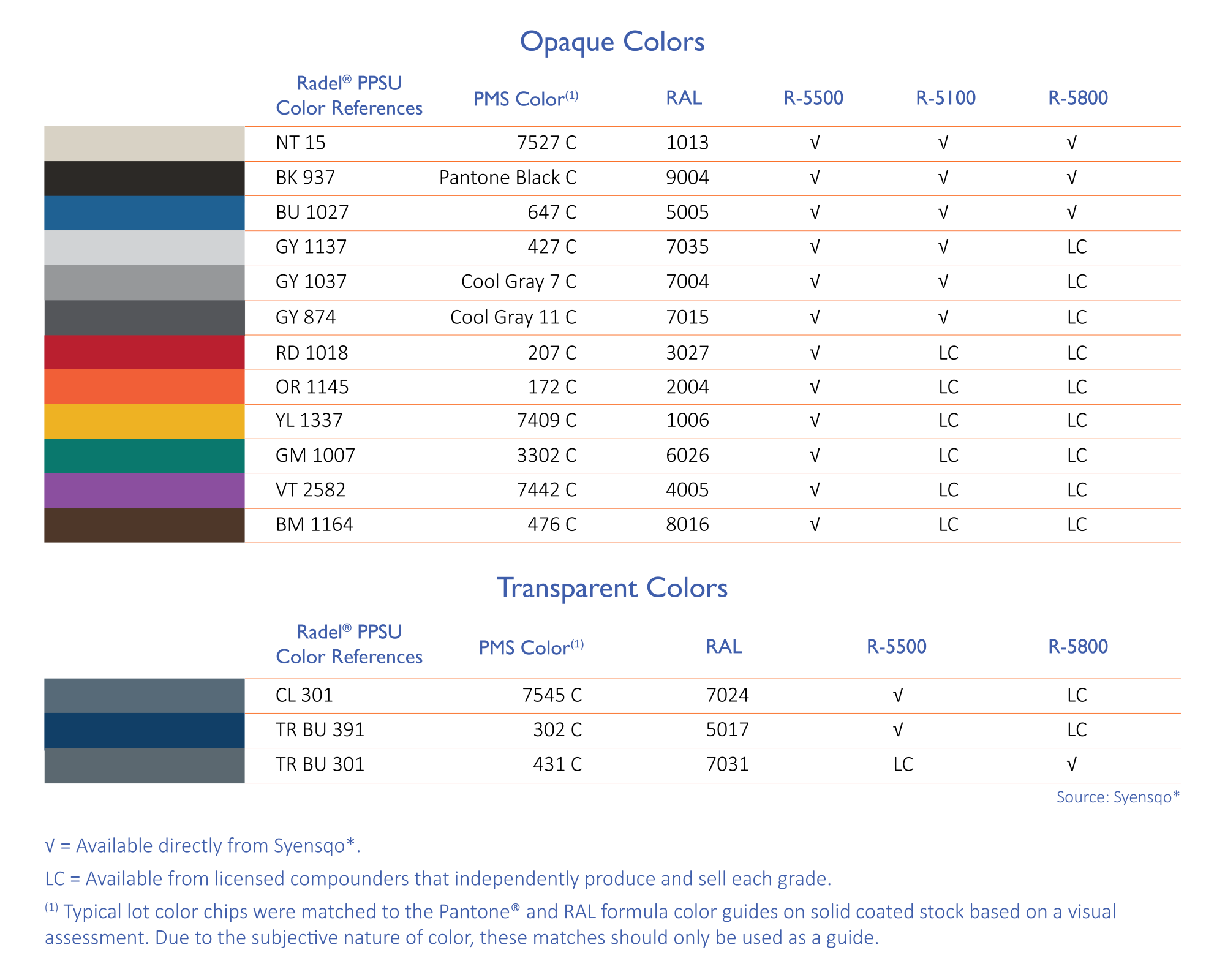

Several grades comprise the Radel PPSU family of healthcare plastics. All share common physical properties. They are transparent amber in their natural form, and available in opaque healthcare industry colors (Table 1).

Impact resistance and good rigidity are among Radel PPSU’s key features. It also resists common chemicals and cleaners used in the healthcare environment. However, it’s most notable attribute compared to most other medical plastics is its ability to withstand far more cycles in all common sterilization techniques without losing appreciable toughness and strength.

What Are the Differences in Radel PPSU Grades?

Radel PPSU grades differ in their melt viscosity, each optimized for different melt processes:

- Radel 5500 is an extrusion grade that Genesis most often converts into machinable stock shapes.

- Radel 5000 can be injection molded or extruded. Genesis offers extruded shapes and injection molded parts in the material.

- Radel 5100 and Radel 5800 are injection molding grades. The 5800 grade has high melt flow, making it preferable for parts with longer flow lengths and/or thin walled sections.